Advanced Manufacturing Capabilities

Equipped with Liebherr 840D gear hobbing machines and Matrix worm grinding systems from Europe, supported by Renishaw laser interferometers and CMM inspection systems. Combines cutting-edge German engineering with expert technical teams to achieve micron-level manufacturing precision.

Precision Transmission Expertise

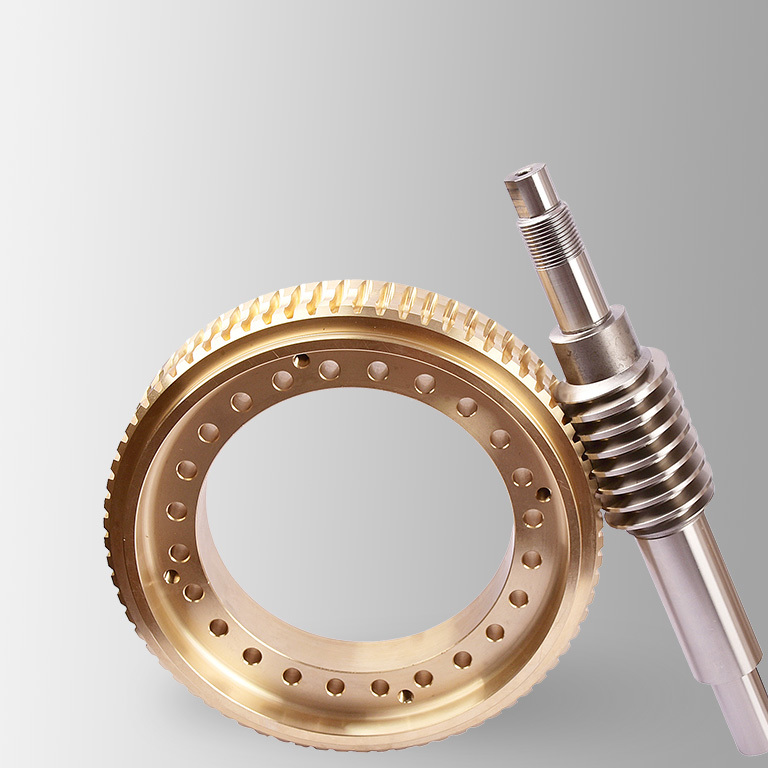

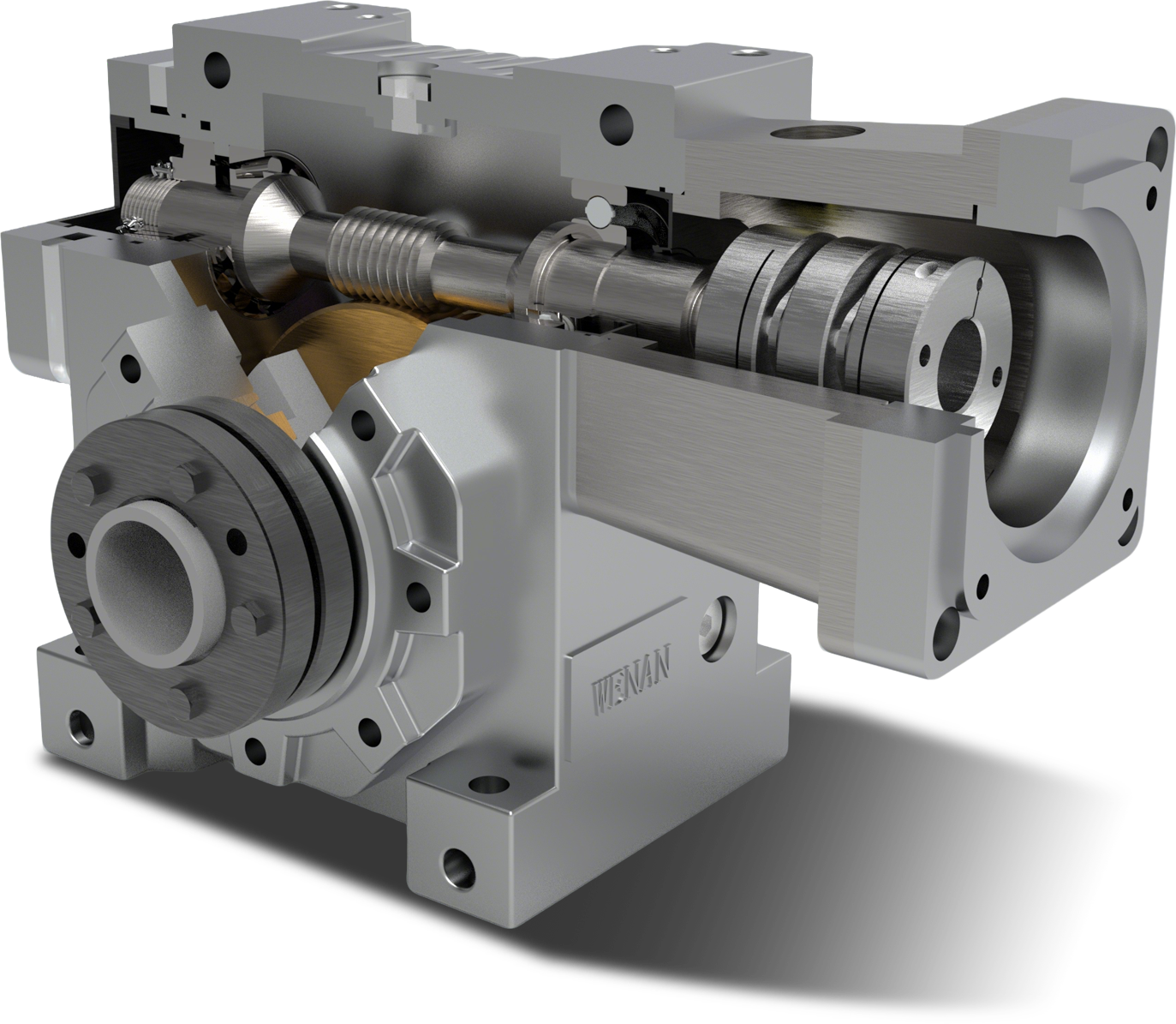

Specializes in DIN Class 2 double lead worm gears and zero-backlash ZC NIMAN reducers with 0.5 arc-min positioning accuracy. Proprietary dual-stage worm drives dominate high-end CNC machining and aerospace applications.

Industry-Specific Engineering Solutions

Delivers customized transmission systems for robotics and medical equipment sectors. Modular designs enable seamless integration with YRT heavy-duty rotary tables in automated production lines.

Sustained R&D Innovation

Implements spiral innovation model with 15% annual revenue reinvestment in equipment upgrades. ISO-certified R&D system ensures reliable technological evolution for global partners.

Search For Relevant Information

Service Covers Multiple Fields

Serving automation, new energy, logistics, 3C semiconductors, medical, food, metallurgy, and petroleum sectors. Reliable solutions trusted globally. Partner with us for precision-driven success.

What We DO

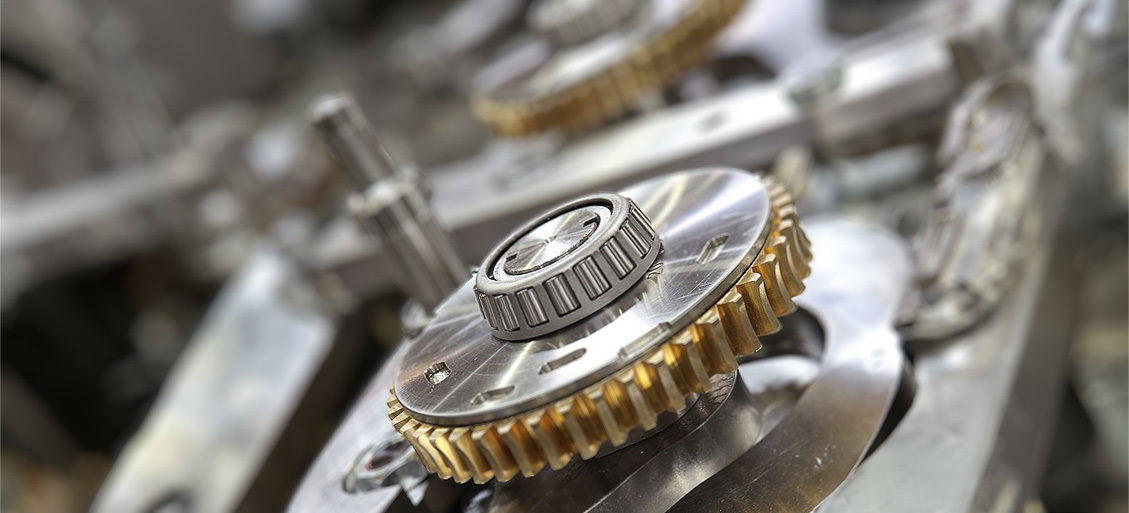

Specializing in high-accuracy worm gear sets, double lead speed reducers, and precision motion control components.

What We DO

Specializing in high-accuracy worm gear sets, double lead speed reducers, and precision motion control components.

WENNAN TECHNOLOGY

Precision in Motion: Global Industrial Solutions Engineered for Tomorrow’s Challenges

Double-lead worm gear pairs achieve DIN Grade 2 accuracy and 0.5 arc-minute positioning precision with zero backlash, ideal for semiconductors, medical devices, and automation.

Utilizes cutting-edge machinery (e.g., Liebherr 840D gear hobbers, Matrix worm grinders) and inspection tools (Renishaw laser interferometers, CMMs) to ensure reliability.

Patented technologies (e.g., dual-stage worm gears) enhance load capacity, efficiency, and durability for heavy-duty and precision applications.

Company

About Wennan Machinery Technology

Precision in Motion, Trust in Transmission Engineering Excellence for a Connected World.

Since its establishment in 2007, Guangdong Wennan Machinery Technology Co., Ltd. has specialized in high-precision worm gear pairs, double lead worm gear reducers, and related precision worm gear products. The company has introduced world-leading production technologies and equipment, including Germany's Liebherr 840D gear hobbing machines, UK's Matrix worm grinding machines, Renishaw laser interferometers, three-coordinate measuring systems, and gear inspection centers. With a team of senior engineers and technical professionals, we ensure cutting-edge manufacturing capabilities.

FAQ

Frequently Asked Questions

What are your core competitive advantages?

What precision standards do your double lead worm gears meet?

What key production equipment do you operate?

Which industries do your products serve?

How do you ensure product reliability?

Blogs & Activity

Guangdong Wennan Machinery Technology Co. Ltd since its establishment many years ago, it has been favored by many domestic and foreign customers, and is committed to the most advanced international turbo-worm and reducer transmission parts.

Guangdong Wennan Machinery Technology Co. Ltd since its establishment many years ago, it has been favored by many domestic and foreign customers, and is committed to the most advanced international turbo-worm and reducer transmission parts.

The Double Lead Hollow Rotating Platform is an innovative device that serves multiple purposes in various industrial applications. Its unique design combines a double lead screw mechanism with a hollow structure, allowing for efficient rotational movement while maintaining a lightweight profile. This makes it particularly beneficial in environments where space and weight considerations are critica

In conclusion, Dual Lead Worm Gears are a reliable, efficient, and versatile solution for modern industrial applications.