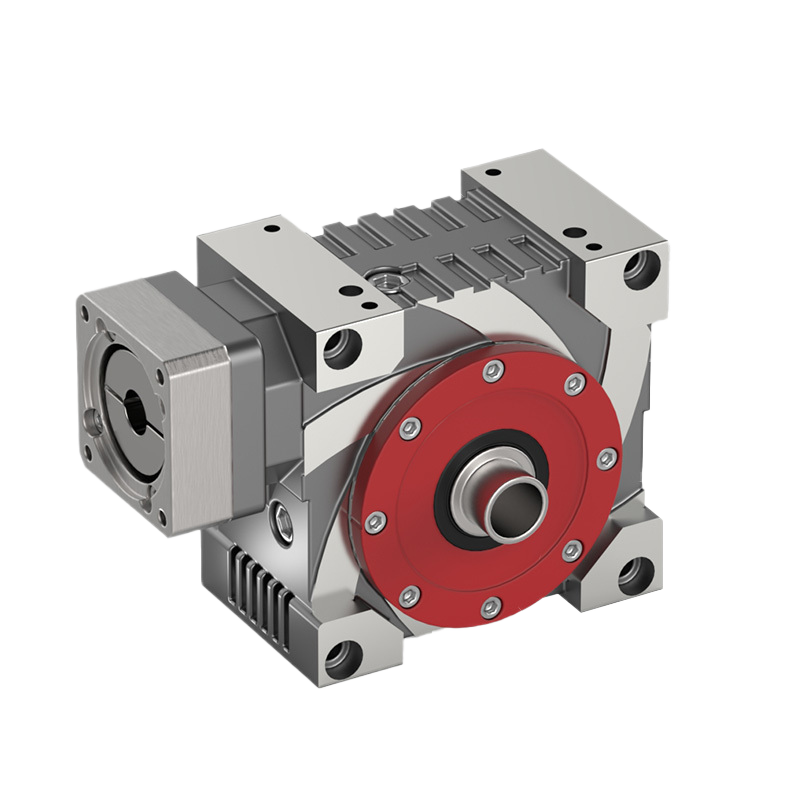

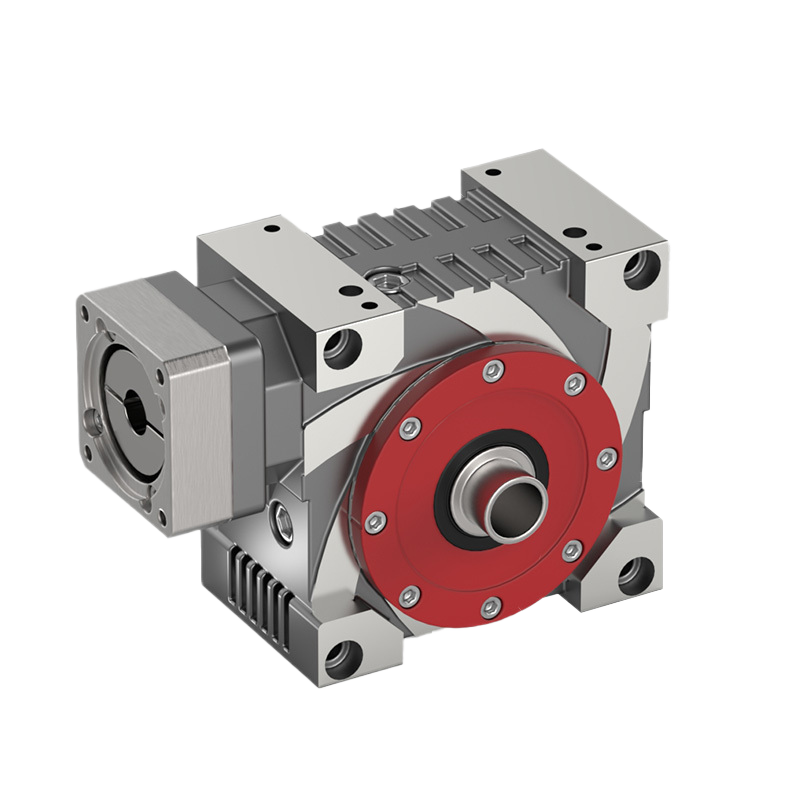

ZC Worm Gear Reducer

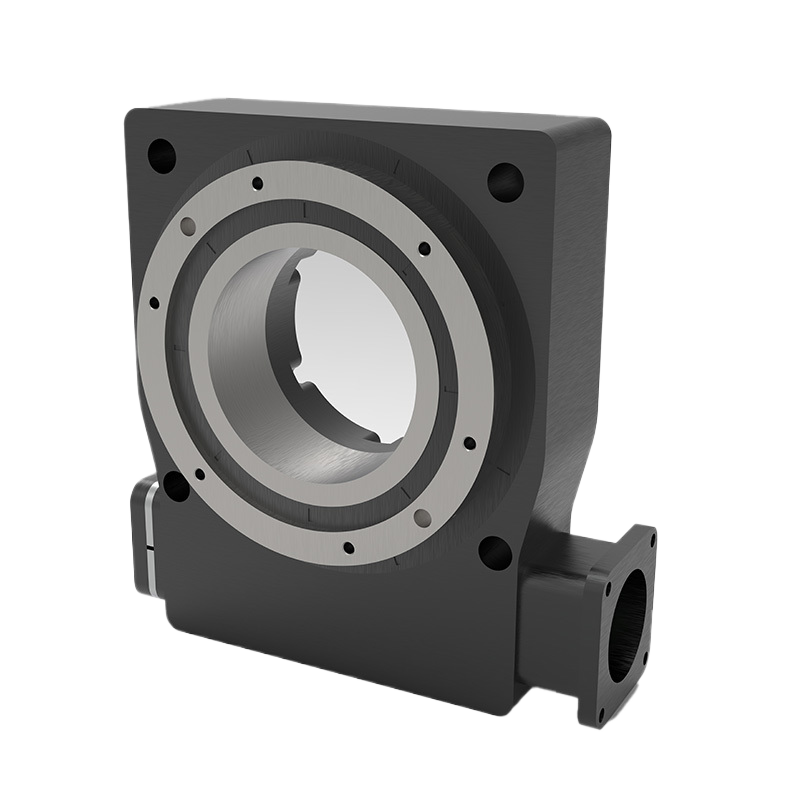

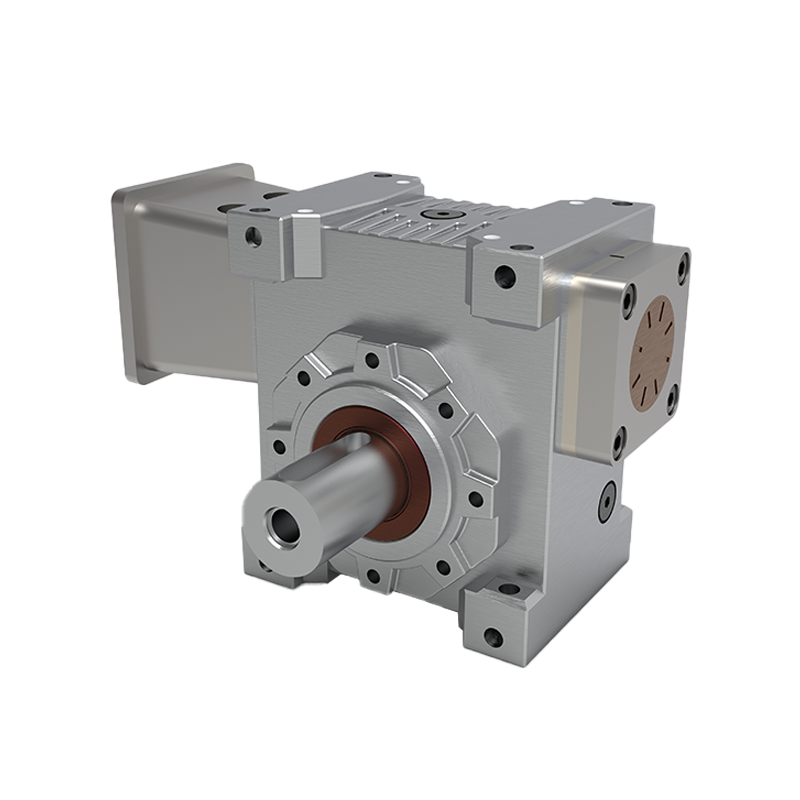

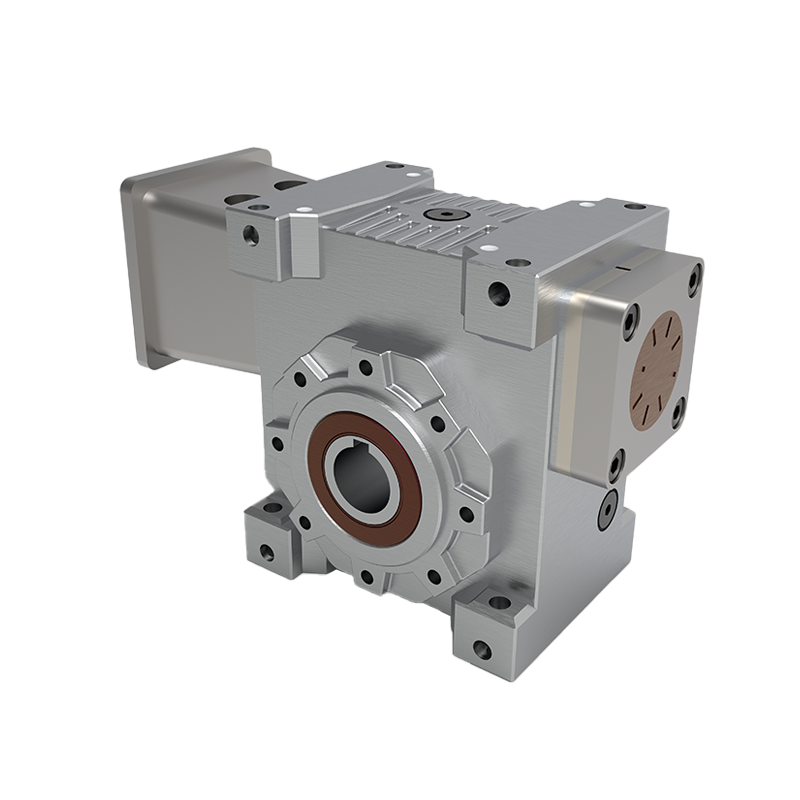

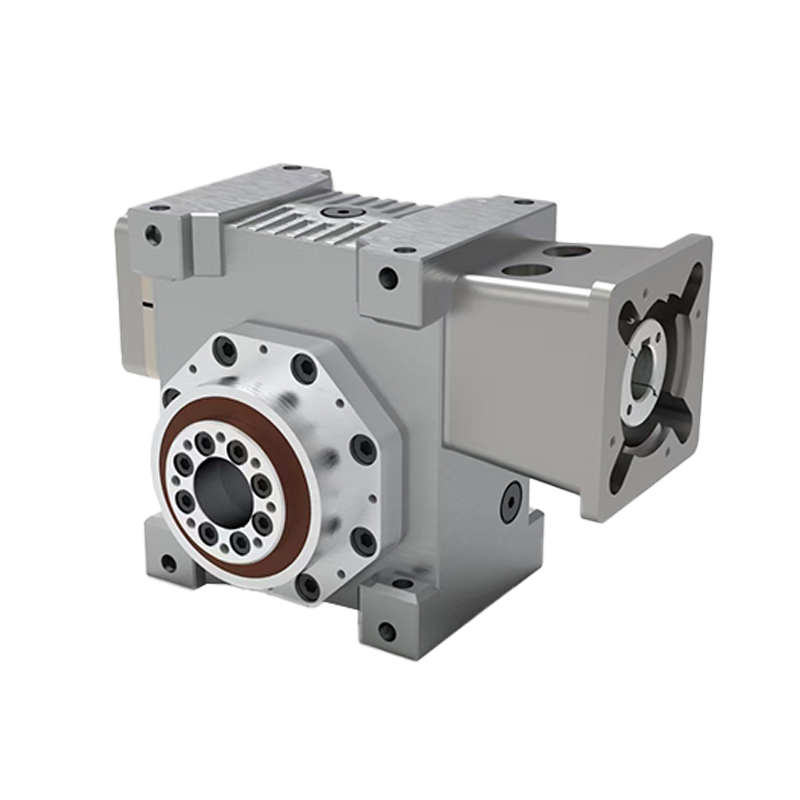

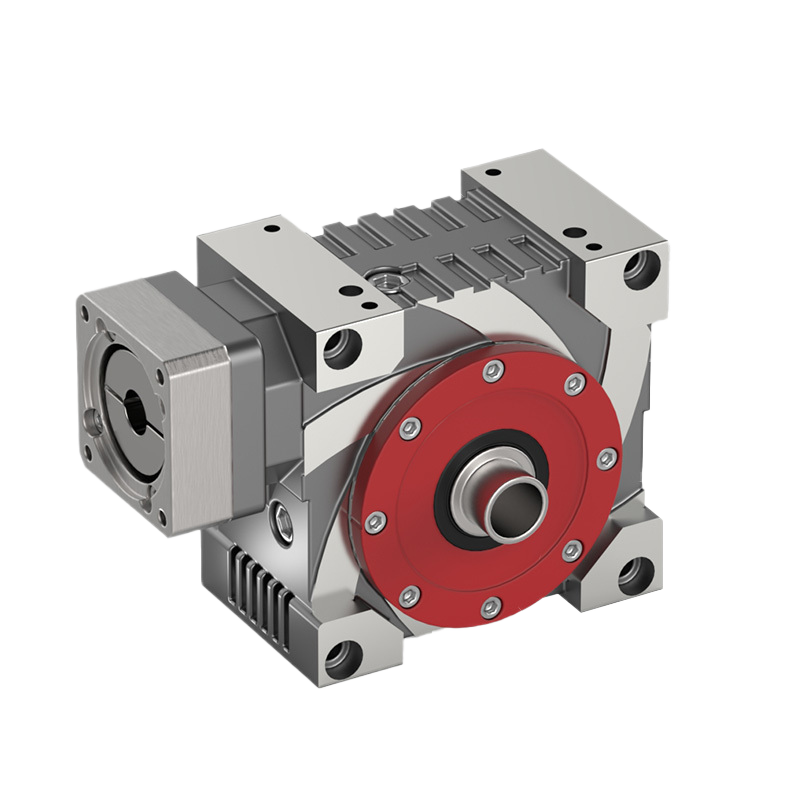

precision worm gear drive A63

The ZC Worm Gear Reducer is a state-of-the-art manufacturing process that delivers up to 98 per cent transmission efficiency and operates at less than 65 decibels, making it suitable for a wide range of industrial scenarios.

In the realm of industrial machinery and motion control systems, the precision worm gear drive stands out for its exceptional performance, largely attributed to its superior quality and unparalleled precision. This product offers a multitude of advantages that are critical for demanding applications.

The inherent design of a high quality precision worm gear drive ensures remarkable durability and longevity, even under continuous heavy-load operations. One of its foremost benefits is the exceptional precision in motion transmission, which guarantees accurate positioning and repeatability crucial for automation and robotics. The self-locking feature enhances safety by preventing reverse driving, adding to its reliability.

Furthermore, a well-manufactured precision worm gear drive operates with minimal vibration and noise, contributing to smoother system integration and improved working environments. The precision engineering involved reduces backlash significantly, leading to more efficient power transmission and lower energy consumption. These drives are also valued for their compact design, providing high reduction ratios in a relatively small footprint.

Ultimately, investing in a precision worm gear drive translates to reduced maintenance costs, fewer operational failures, and enhanced overall system quality. The consistent precision and robust construction make it an indispensable component where reliable and accurate rotational movement is paramount.

Therefore, the precision worm gear drive exemplifies how advanced manufacturing quality directly results in operational excellence and long-term value.

A63 | ||||||||||

速比/i |

| 4 | 7 | 10 | 16 | 28 | 40 | |||

最大力矩/T2a | Nm | 319 | 353 | 364 | 372 | 392 | 363 | |||

in.lb | 2823 | 3124 | 3221 | 3292 | 3469 | 3213 | ||||

恒定回程间隙的扭矩/T2servo | Nm | 198 | 210 | 225 | 221 | 229 | 226 | |||

in.lb | 1752 | 1859 | 1991 | 1956 | 2027 | 2000 | ||||

紧急制动力矩/T2not | Nm | 460 | 484 | 491 | 494 | 518 | 447 | |||

in.lb | 4071 | 4283 | 4345 | 4372 | 4584 | 3956 | ||||

允许的平均输入转速/∩1N | rprm | 4000 | ||||||||

最大输入转速/∩1Max | rprm | 4500 | ||||||||

空载运行平均扭矩/T012 | Nm | 4.2 | 3.1 | 3 | 2.4 | 2.3 | 2.2 | |||

in.lb | 37.2 | 27.4 | 26.6 | 21.2 | 20.4 | 19.5 | ||||

最大回程间隙/jt | arcmin | 标准≤3/定制≤2 | ||||||||

扭转刚度/Ct21 | Nm/arcmin | 28 | ||||||||

in.lb/arcmin | 248 | |||||||||

最大轴向力/F2AMax | N | 8250 | ||||||||

lbf | 1856 | |||||||||

最大径向力/F2QMax | N | 6000 | ||||||||

lbf | 1350 | |||||||||

最大侧倾力矩/M2KMax | Nm | 843 | ||||||||

in.lb | 7461 | |||||||||

满载效率/ŋ | % | 93 | 91 | 88 | 83 | 74 | 68 | |||

寿命/Lh | h | >20000 | ||||||||

重量/m | kg | 13.0 | ||||||||

lbm | 28.7 | |||||||||

运行噪音/LPA | dB(A) | ≤64 | ||||||||

允许的最高外壳温度 | ℃ | +90 | ||||||||

F | 194 | |||||||||

环境温度 | ℃ | -15至+40 | ||||||||

F | 5至104 | |||||||||

润滑 |

| 终生润滑 | ||||||||

旋转方向 |

| 输入输出同向 | ||||||||

防护级别 |

| IP65 | ||||||||

转动惯量 | H | 28 | J1 | kgcm² | 4.80 | 3.89 | 3.65 | 3.56 | 3.52 | 3.47 |

10‾³in.lb.s² | 4.25 | 3.44 | 3.23 | 3.15 | 3.12 | 3.07 | ||||

*Support drawings and samples customization

- Features:

- Constant low backlash throughout the entire service life ensures high quality and positioning accuracy without stick-

- Thanks to the reinforced cylindrical teeth, the optimized output bearing can withstand extremely high axial and radial

- The cylindrical teeth have a high overload resistance due to the low specific tooth pressure.

What’s Next?

CAD & 3D Drawings

Download Now

Installation & Maintenance

Read Now

Application Examples

Read Now

Other Models Available

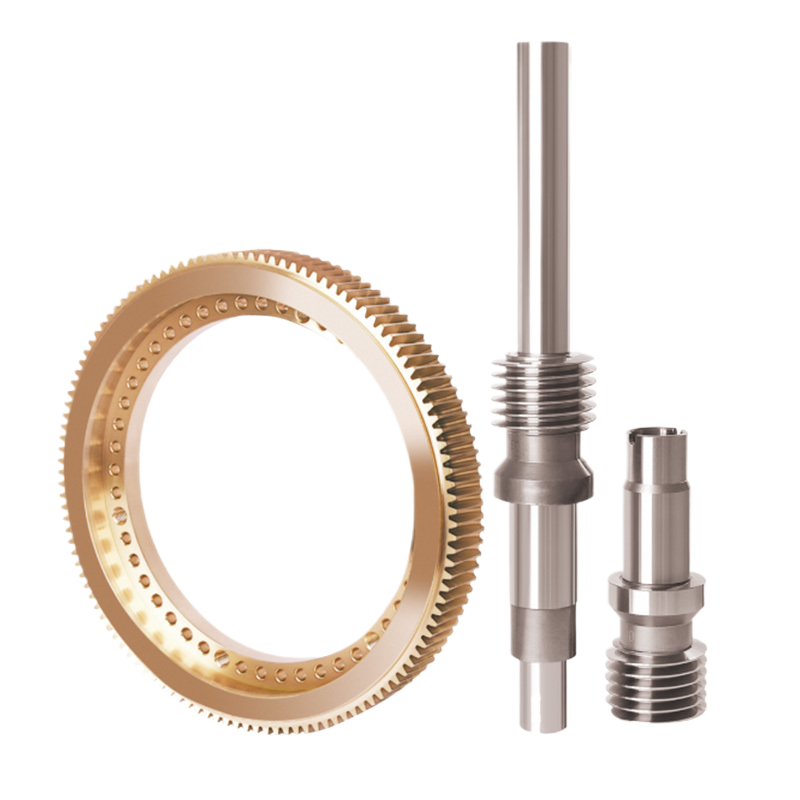

Worm Gears

-

Dual Lead Worm Gears

Wennan Machinery Technology is a quality dual lead worm gear wholesale company in China, offering OEM services, competitive pricelists, and customized solutions for global manufacturers and suppliers.

-

Double Stage Worm Gear

Wennan Machinery Technology is a leading company specializing in advanced Double Stage Worm Gear spots, offering customized OEM solutions, competitive pricelists, and wholesale services through reliable factory and supplier networks.

-

precision worm gear

Wennan Machinery Technology is a leading china precision worm gear spots company offering wholesale, OEM, customized solutions with competitive quotation and pricelist for global manufacturers and suppliers.

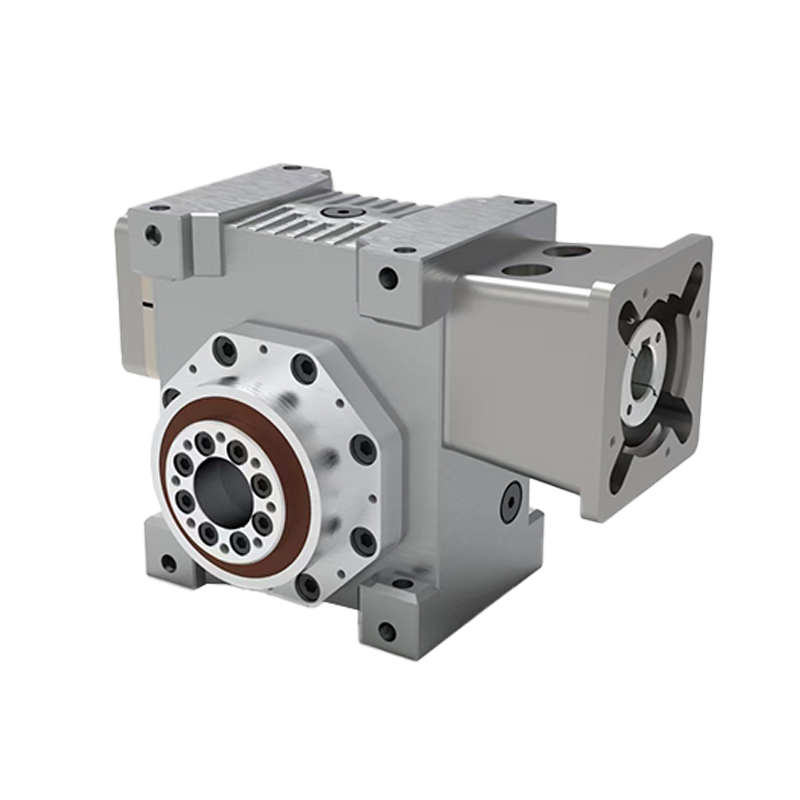

Dual Lead Worm Gearbox

-

Double Lead Worm Gear Reducer

Wennan offers newest dual lead worm gear solutions as a China manufacturers & suppliers company, providing customized OEM options, wholesale pricelists, and reliable factory-quality service.

-

Double Lead Worm Gear Reducer-Hollow Shaft Output

Wennan Machinery Technology is a leading company specializing in customized worm gear reducers, offering free samples, OEM services, competitive pricelists, and wholesale options from our trusted factory and suppliers.

-

Double Lead Speed Reducer-Solid shaft output

Wennan Machinery Technology is a leading company specializing in customized Double Lead Speed Reducer manufacturing, offering OEM services, wholesale pricing, and reliable supplier solutions.

-

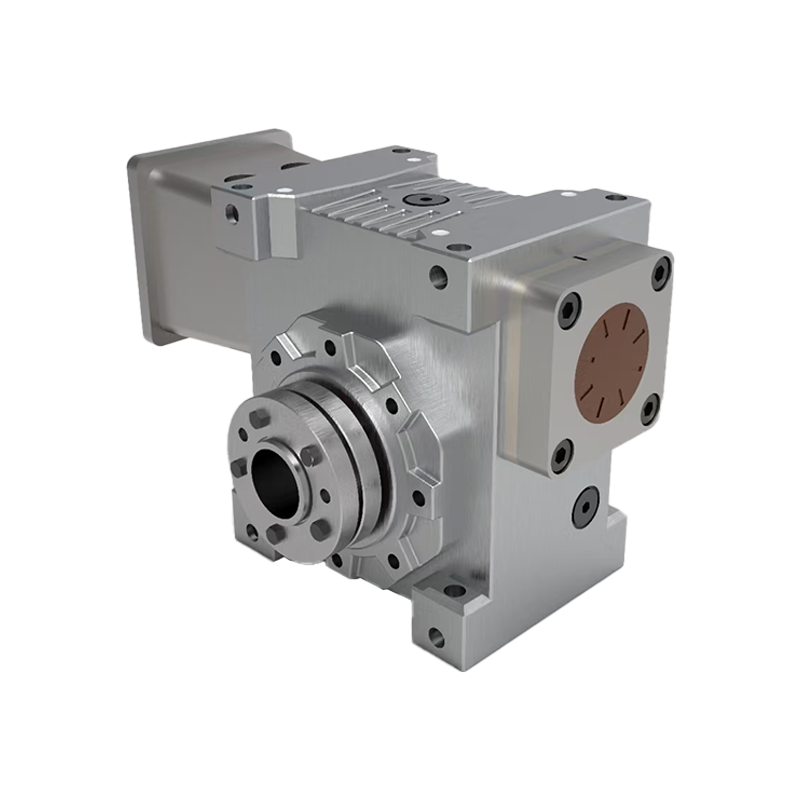

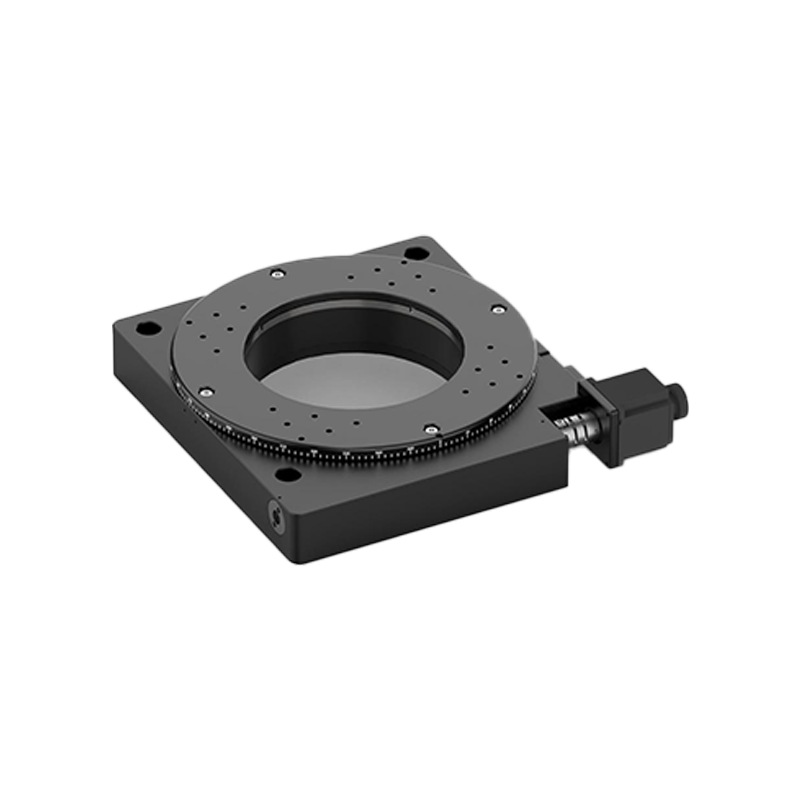

high precision hollow rotating platform

-

dual lead worm gearbox

Wennan Machinery Technology offers the newest dual lead worm gearbox china with OEM customized service, wholesale pricelist, factory quotation, and reliable brands suppliers for global manufacturers.

-

Double Lead Reducer

Wennan Machinery Technology is a leading China manufacturer and supplier specializing in wholesale Double Lead Reducers, offering customized OEM services, competitive pricelists, and reliable factory spots.

Dual Lead Hollow Rotary Platform

ZC Worm Gear Reducer

-

high precision worm reducer

Wennan Machinery Technology is a wholesale high precision worm reducer company offering customized OEM solutions with competitive quotation, pricelist, and reliable factory suppliers for global brands.

-

ZC Worm Gear A40

Wennan Machinery Technology is one of the leading China ZC Worm Gear manufacturers, offering OEM services, customized solutions, and competitive wholesale quotations for global brands and suppliers.

-

precision worm gear drive A63

Wennan Machinery Technology is a quality precision worm gear drive factory in China, offering brands, quotation, pricelist, customized OEM, wholesale spots, and trusted manufacturers & suppliers service.

-

anti-backlash worm gear A80

Wennan Machinery Technology is a trusted advanced anti-backlash worm gear wholesale company offering brands, quotation, pricelist, customized OEM solutions, and reliable factory manufacturers suppliers.

-

zero backlash worm gear A100

Wennan Machinery Technology is a trusted OEM zero backlash worm gear manufacturer made in China, offering wholesale, customized solutions, quotation, pricelist, and reliable factory supply for global brands.

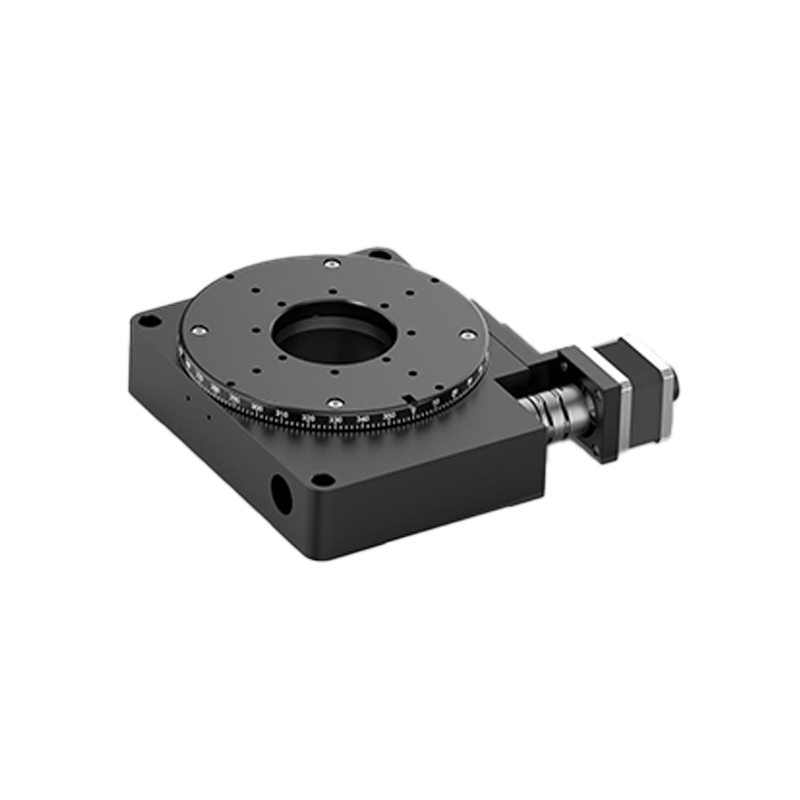

Motorized Rotary Table & Manual Angle Table

-

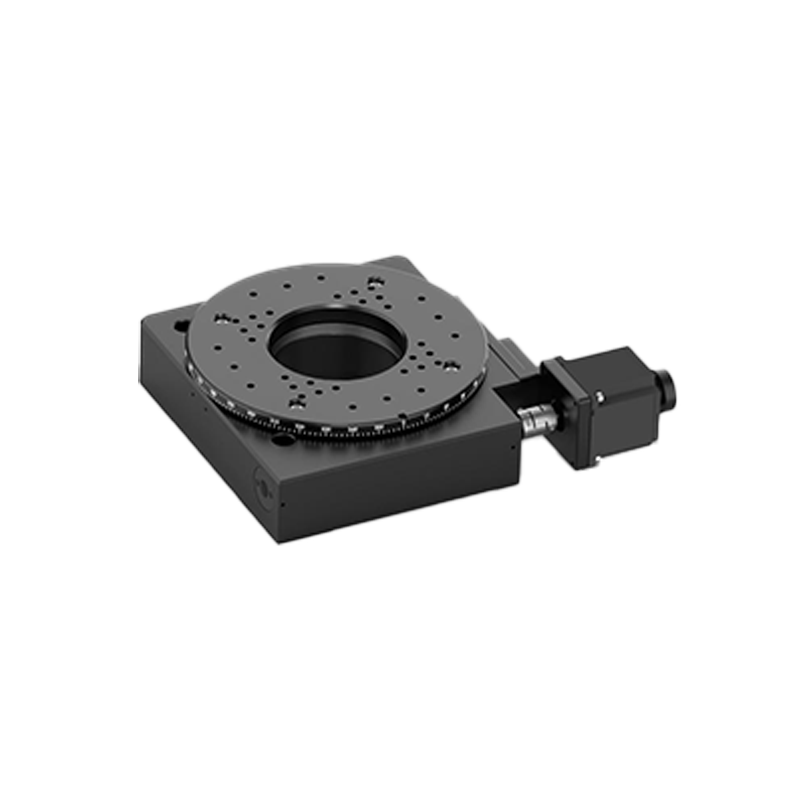

advanced high precision hollow rotating platform source

Wennan Machinery Technology is a leading company and factory specializing in advanced high precision hollow rotating platforms, offering OEM, customized solutions, wholesale, and reliable supplier services.

-

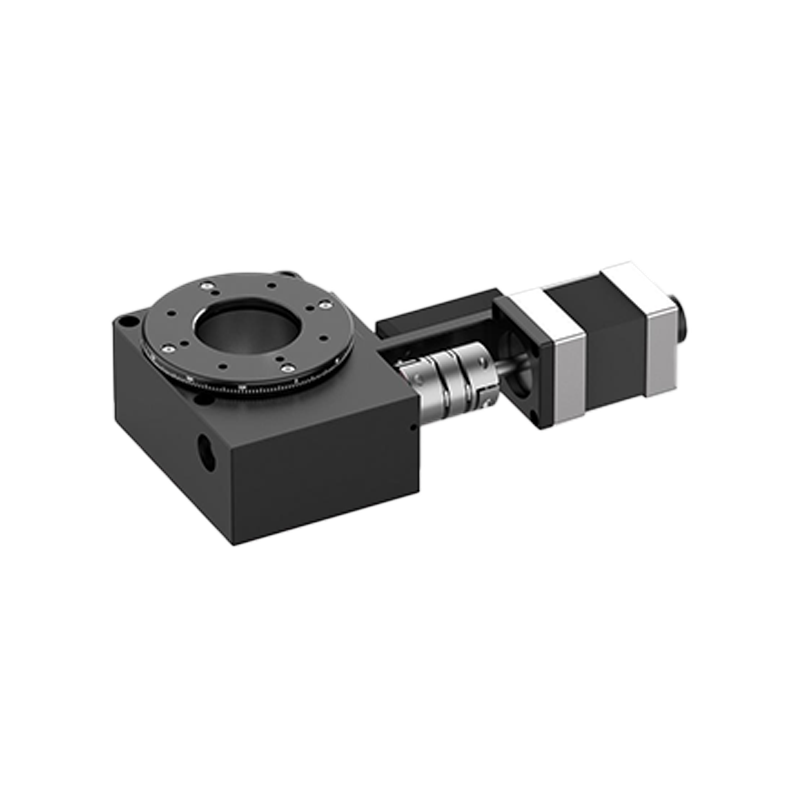

zero backlash worm gearbox-Electric Rotary Table 150

Wennan Machinery Technology is a leading company and OEM manufacturer specializing in quality zero backlash worm gearboxes, offering customized solutions, wholesale options, and competitive pricelists.

-

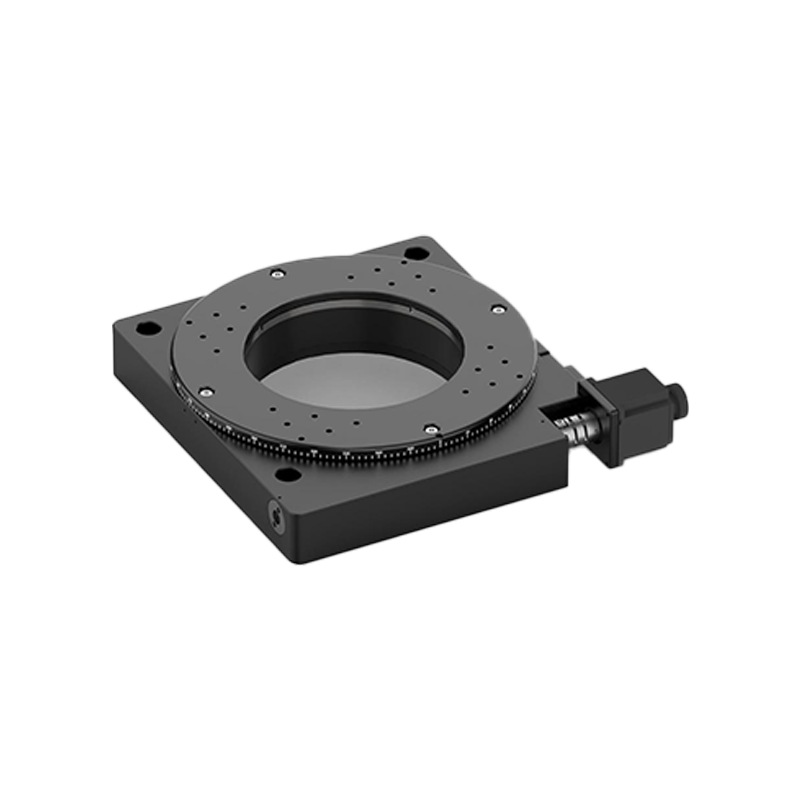

high precision worm gear reducer-Electric Rotary Table 200

Wennan Machinery Technology is a China-based company specializing in high precision worm gear reducer manufacturing, offering customized solutions, OEM services, wholesale, and competitive pricelists.

-

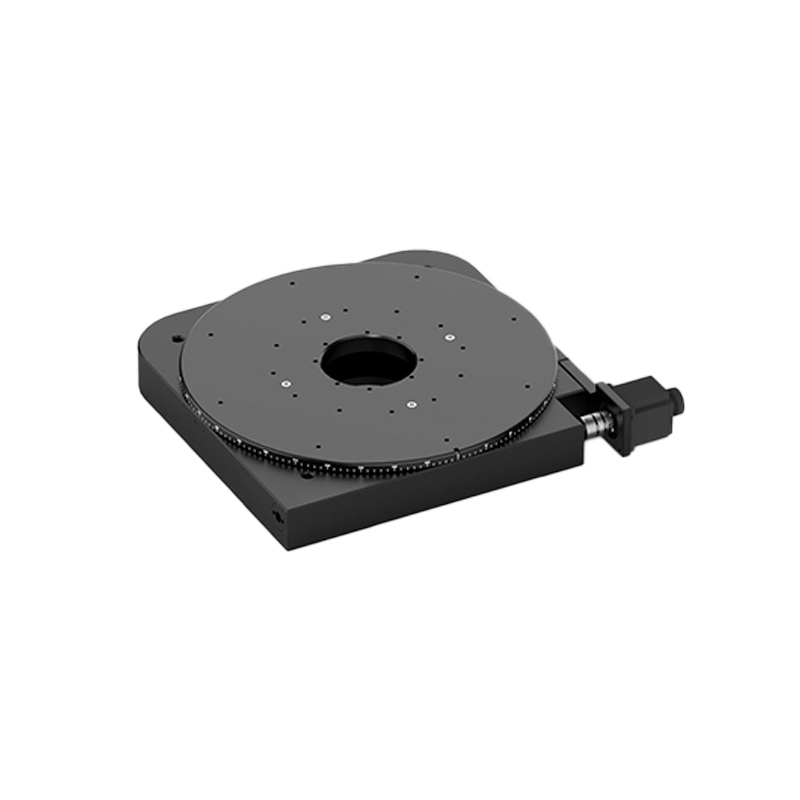

high accuracy rotating platform 300

Wennan Machinery Technology is one of the best high accuracy rotating platform manufacturers, offering wholesale, OEM, customized solutions with pricelist, quotation, and reliable factory supply.

-

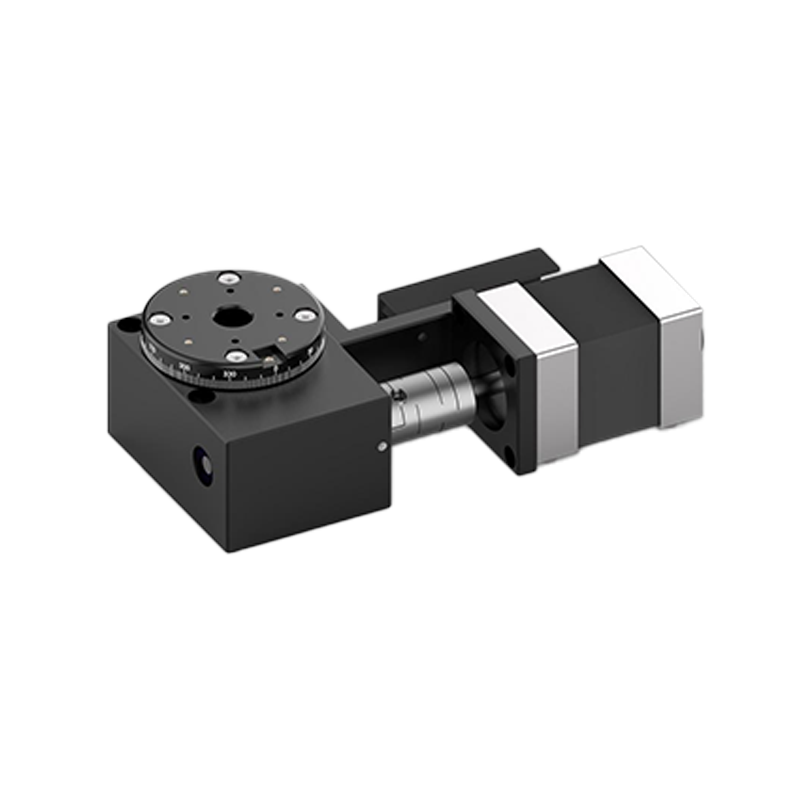

right angle worm gearbox-Corner Table 40-25

Wennan Machinery Technology, newest right angle worm gearbox suppliers in China, offers brands, quotation, pricelist, customized OEM, wholesale spots, serving as a trusted company, factory, and manufacturers.

-

Manual Corner Table

-

Electric Rotary Table 400

-

Electric Rotary Table 100

-

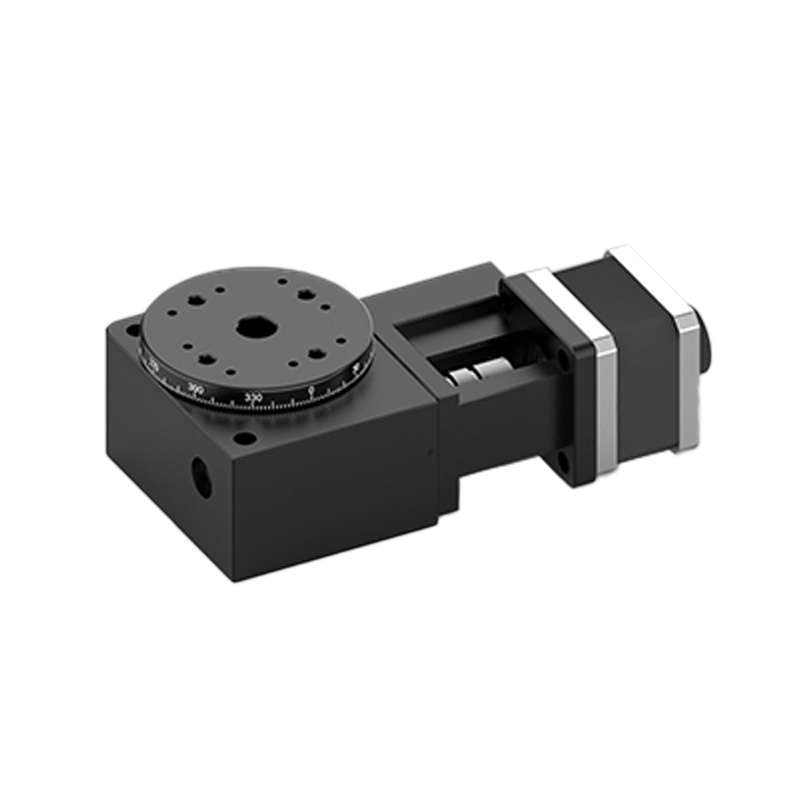

Electric Rotary Table 40

-

Electric Rotary Table 60-90

-

Electric Rotary Table 60-180

-

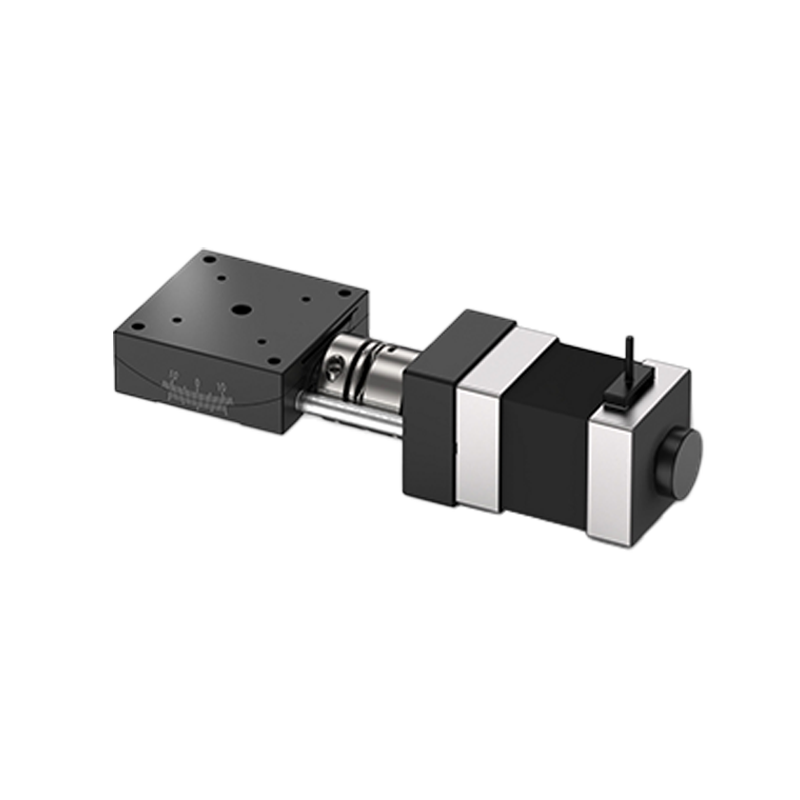

Corner Table 40-40

-

Electric Corner Table

-

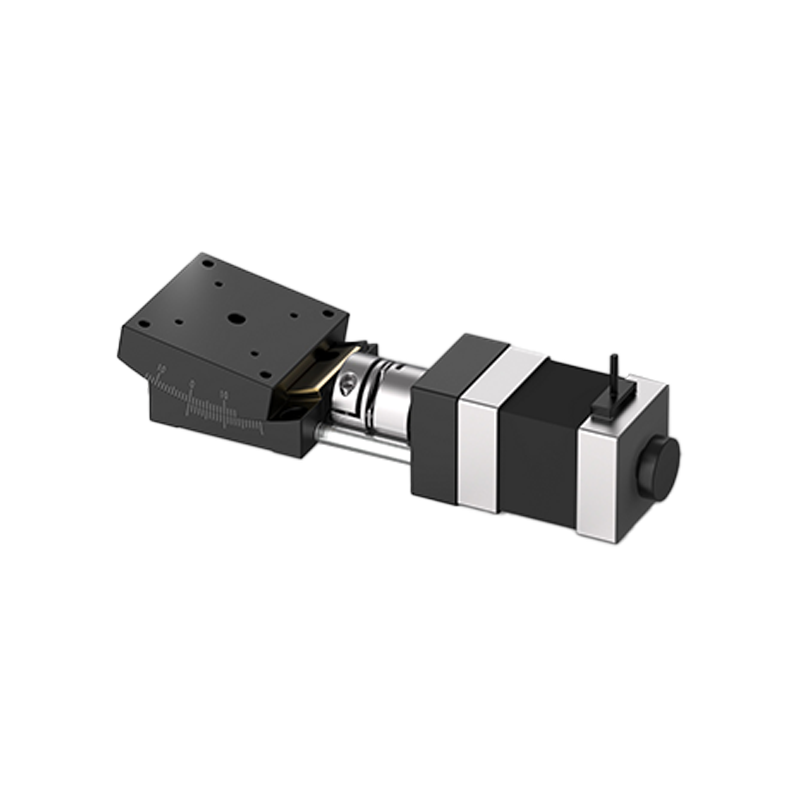

Electric Corner Table 40-25

-

Electric Corner Table 40-40

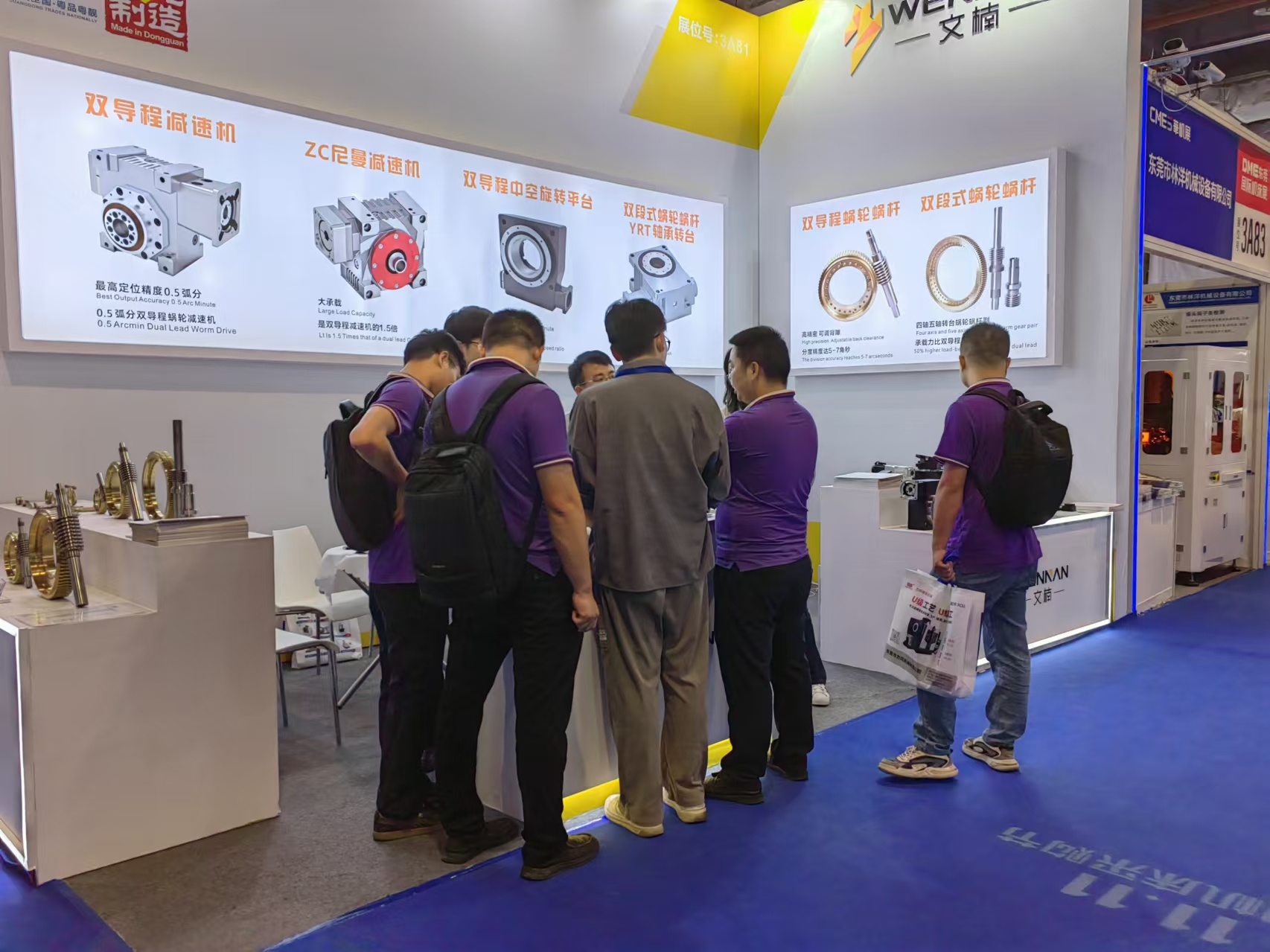

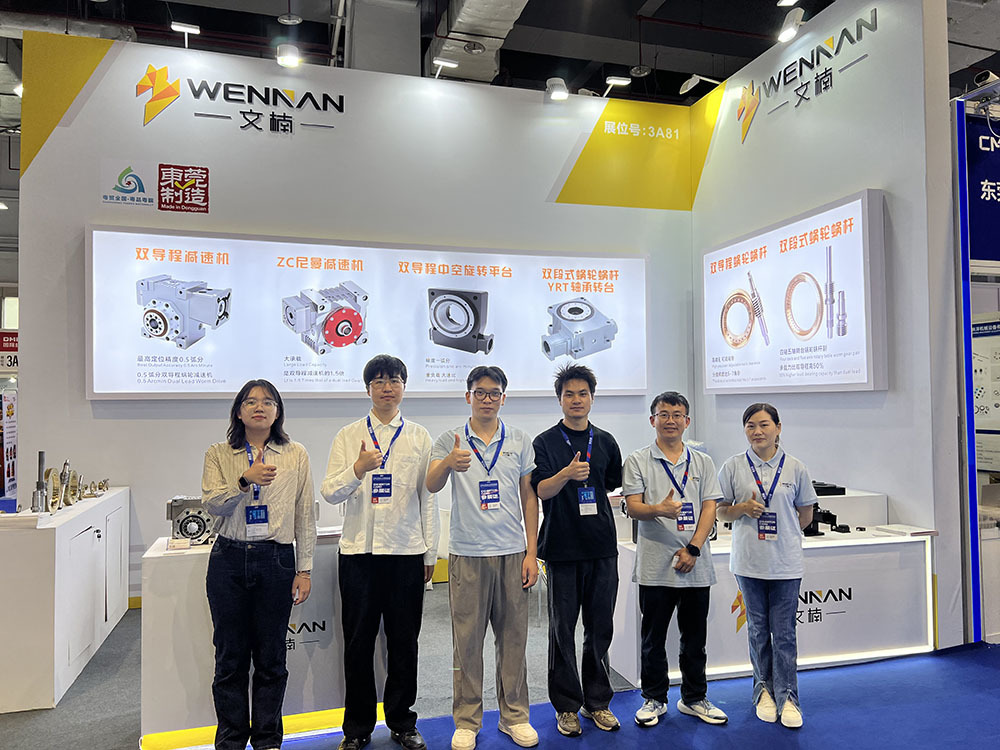

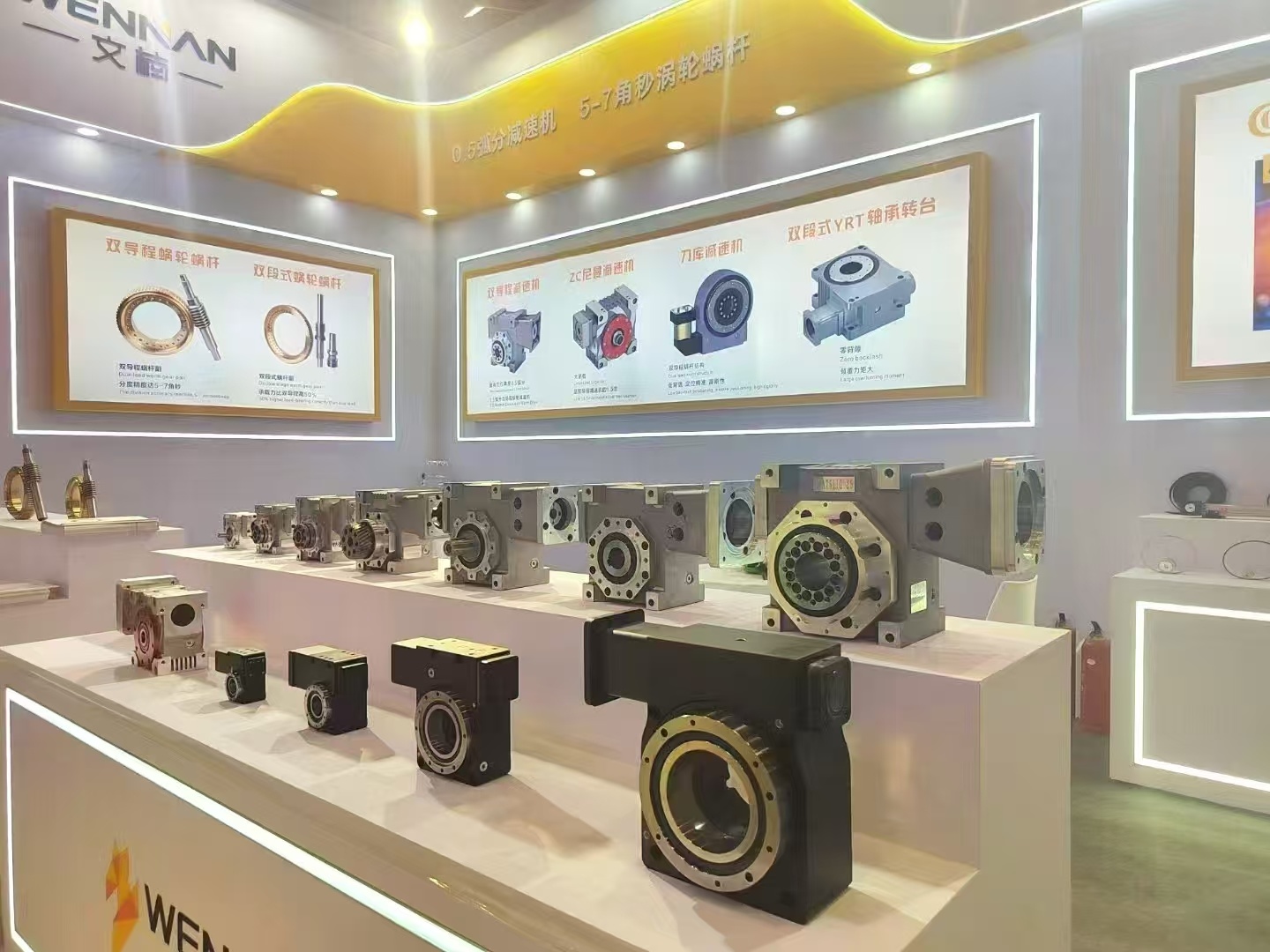

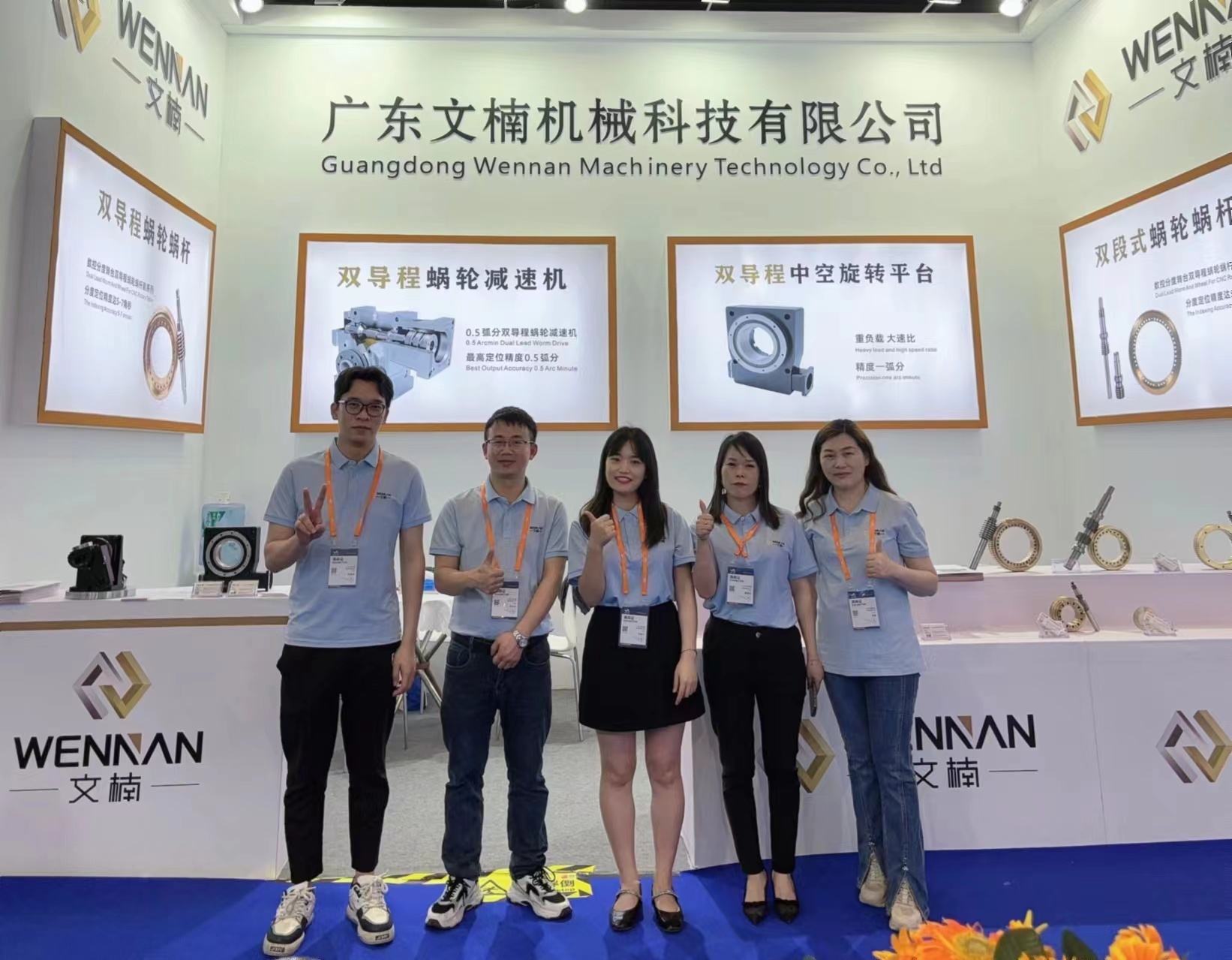

Exhibition

-

Exhibition

Wennan is a newest high accuracy rotating platform manufacturers company and factory, offering trusted brands, customized OEM solutions, wholesale spots, clear quotation and pricelist support for global suppliers and manufacturers.

-

Exhibition

-

Exhibition

-

Exhibition

-

Exhibition

-

Exhibition

-

Exhibition

-

Exhibition

-

Exhibition

-

Exhibition

-

Exhibition

-

Exhibition

AP

Automation

New Energy

Warehousing And Logistics

3C semiconductor

Medical

Food

Metallurgy

Petroleum

Our Factory

-

Worm Grinding Machines (UK)

Wennan is a China ZC Worm Gear manufacturers company and factory, serving global suppliers with brands, customized OEM wholesale spots, offering quotation and pricelist.

-

Quality Department

Wennan is a China Dual Lead Worm Gears suppliers company and factory, offering brands, quotation, pricelist, customized OEM wholesale spots for manufacturers and suppliers.

-

Liebherr CNC Hobbing Machines From Germany

Wennan is a China worm gearbox factory and company offering brands services as manufacturers and suppliers with customized OEM wholesale spots, providing quotation and pricelist.

-

Workshop

Wennan is a China custom precision gearbox exporters company and factory, serving global brands with customized OEM wholesale spots, offering quotation and pricelist support as trusted manufacturers and suppliers.

-

Factory

Wennan is a China zero backlash worm gear company offering brands quotation pricelist customized OEM wholesale spots services as a factory and company for manufacturers and suppliers worldwide.

-

Warehouse

Wennan is a China high precision worm reducer OEM company, offering customized brands quotation and pricelist, supporting wholesale spots supply as a factory among reliable manufacturers and suppliers.

-

Workshop 1

Wennan is one of the best low backlash rotating table brands, a factory company serving manufacturers and suppliers with OEM customized solutions, wholesale spots, and clear quotation and pricelist.

相关产品

Why Choose WENNAN?

Since its establishment in 2007, Guangdong Wennan Machinery Technology Co., Ltd. has been focusing on the production of double lead worm gear pairs, with the highest accuracy reaching German standard DIN 2 level. The company also produces ZC Niman worm gear rods for the elevator industry, as well as double segment worm gear rods, high-precision double lead reducers, double lead hollow rotary platforms, zero backlash, positioning accuracy up to 0.5 arc minutes, and precision worm gear electric circular tables, corner tables, and other worm gear related products. The company has production and testing equipment such as the German Liebherr 840D gear hobbing machine, the British Maicuis worm gear grinder, the British Renishaw laser interferometer, three coordinate, and gear testing centers, which are widely used in mechanical equipment transmission devices in various industries such as automation, new energy, warehousing and logistics, 3C semiconductors, medical, food, metallurgy, and petroleum. The quality is stable and reliable, and it is favored by domestic and foreign users. We warmly welcome friends from all walks of life at home and abroad to cooperate sincerely.

Sample Industries

Automation

New Energy

Warehousing And Logistics

3C semiconductor

Medical

Food

Metallurgy

Petroleum